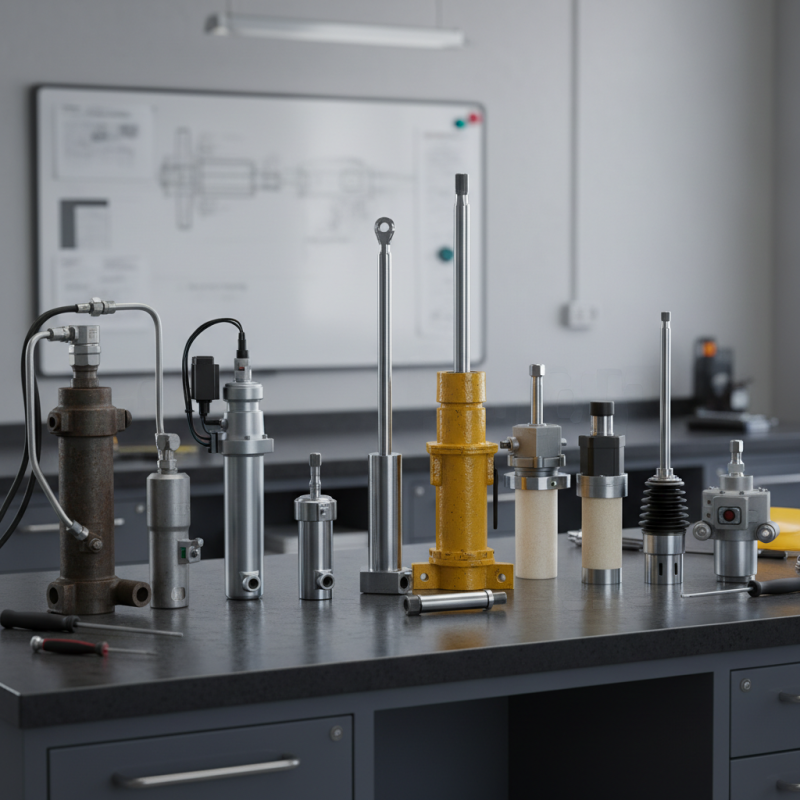

| Rod Type Steering Cylinder | Uses a rod to transfer force for steering. | Heavy-duty trucks and machinery. | High durability and strength. |

| Compact Steering Cylinder | Space-saving design for tight areas. | Small vehicles and equipment. | Lightweight and efficient. |

| Double Acting Steering Cylinder | Acts in both directions for better control. | Buses and larger vehicles. | Provides enhanced steering response. |

| Power Steering Cylinder | Uses hydraulic power for steering assistance. | Passenger cars and trucks. | Reduces steering effort significantly. |

| Single Acting Steering Cylinder | Moves in one direction; spring returns. | ATVs and gardening equipment. | Simple design and cost-effective. |

| Tilt Steering Cylinder | Allows steering wheel angle adjustment. | Trucks and SUVs. | Improves driver comfort and ergonomics. |

| Articulated Steering Cylinder | Jointed for better maneuverability. | Agricultural and construction machinery. | Enhanced agility on varied terrain. |

| Variable Assistance Steering Cylinder | Offers different levels of assistance. | Luxurious cars and high-end vehicles. | Personalized steering experience. |

| Internal Gear Steering Cylinder | Nuts and gears for precise motion. | Forklifts and industrial equipment. | High precision and stability. |

| E-Power Steering Cylinder | Electric assistance for energy saving. | Electric vehicles and modern cars. | Eco-friendly and efficient. |